Story

I had a fair amount of extra wood lying around from the various deck

related projects from the previous year (see Decks, Deck Screen and Deck Furniture). This wood

consisted of pressure treated 2x6's and 2x4's, plus some Ipe 1x6 and

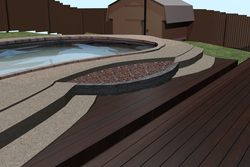

1x4 deck boards. This wood was originally slated for an oddly shaped

area between the new decks and the pool. The proposed plans for this

consisted of some steps and planters, which are shown on the Deck Perimeter Project

Page. To save on delivery charges, I bought the wood for this in

advance of having a firm plan, since I needed to gte the wood for the

project Deck Furniture - Phase

II.

I grew dissatisfied with the initial plans and later decided not to

follow through with the wooden steps idea, and went with paving stones

instead. The extra wood sat there for about 9 months before I had a

plan for it. The wood was also preventing me from being able to park

my car in the garage, so I was motivated to find a use for it.

With the new deck and removal of the old decks, we were left with a

somewhat barren area toward the rear of the property. Creating

planters that would match the deck seemed to be a good combination of

being functionality useful, visually adding to the backyard and

consuming the extra wood.

Details

The trickiest parts of designing planters for this project were the

constraints:

- needs to be very sturdy to hold the weight of a lot of soil and pots;

- should be relatively simple to construct;

- needs to tolerate standing water/soil well; and

- needs to be made with only the remaining materials.

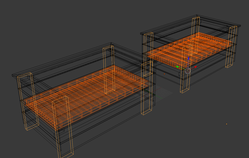

As usual, I created the design

using the Blender software.

What proved the most difficult though was designing the flooring that

the plants woudl sit on. I did not like the idea of direct contact

between the pots/soil/water and wood. I thought about and researched

various rubber and plastic coatings I could use, though about plastic

supports, but then found these sturdy, marine-grade plastic bases that

were designed for use in artificial waterfalls. They were meant to be

submerged and have heavy rocks on them, so fit my requirements

perfectly. They were 2 feet by 4 feet, which was just about the size I

was planning on for the platers, so I modified the designs to

accomodate theitr exactly dimensions.

Once the design was complete, the building was straigh-forward and

uneventful. I used the extra stainless steel screws I had from the Deck Furniture project to ensure

it would hold up to the elements. I first cut the frame pieces out of

pressure treated wood. I decided to assemble the frame first so I

could get precise measurements for the Ipe pieces that would be the

exterior surfaces. Because every edge on the Ipe needed to be mitered,

and because I had very little margin for error in the amount of Ipe

wood I had, I did not want to risk any mistakes.

Though the legs were pressure treated wood, the treatment does not

always fully penetrate the wood. When you cut the wood, if the end

grain is exposed to the elements, there is some chance it will not hold

up as well as the uncut and better treated parts of the wood. The cut

ends of the legs of the planetsr woudl be sitting directly on the

ground (concrete though), but still would often sitting in water.

Thus, I wanted to make sure the end grains were liberarlly sealed with

some outdoor paint. There was just a little bit extra left-over paint,

so it was used on the rest of the frame as some additional protection

(it would have dried up in the can by the next time I went to use the

leftover).

The overall dimensions of the planter were dictated by the plastic

bases that I bought, so this determined the lengths of the Ipe boards I

would need to cut for the outside. I originally thought to make 3

planters when the design was a little smaller, but the plastic base

required a larger footprint, so I could only make 2 planters.

To make the appearance as nice as possible, I beveled every edge of the

Ipe, which was a breeze with my relatively new miter saw. This was

have been a bigger pain to do on my table saw, and likely not as

precise. I also had left-over oil stain from the deck, which was just

about the right amount for the boards.

I wound up about 2 feet short of the Ipe 1x6 boards I needed. I dealt

with this by modifying the design so the lowest side pieces were 1x4

pieces instead. The official reason for this design change was that it

would prevent leaves from accumulating under the planters and make it

easier to blow the leaves out. It is not all that noticable, as the

picture at right shows.

Final Results

In the end, I had very little Ipe wood left and used all the good

pressure treated lumber (there were some really crappy pieces I got

delivered but did not notice until too late). The only thing I needed

to buy was the plastic bases and all else was from the leftovers. The

end result wound up being much, much heavier than I anticipated:

probably a good 200 pounds each. I had to call a friend to help move

them from the garage to the backyard.

Cassandra.org

Cassandra.org